1. Introduction

Altizon, a global industrial IoT company, headquartered in Palo Alto (USA) with offices in Boston (USA) and Pune (India), powers digital revolutions by helping enterprises leverage machine data to drive business decisions. Altizon has been spearheading digital transformation initiatives in Industry 4.0 across a range of industry verticals, including Automotive, Tire, Consumer Packaged Goods (CPG), Chemicals and Remote Industrial Assets.

Established in 2013, Altizon launched its proprietary Datonis Internet of Things (IoT) platform in Oct 2013 to provide enterprise-grade technology across the functional breadths of operations to deliver rapid business outcomes. Since inception, Altizon has attracted the first round of Series A funding for $ 4 million in 2016, consequent to which it expanded its operations in the U.S. In Apr 2019, Altizon secured a second round of $ 7 million in A series funding that is being utilised to strengthen international presence and support investments in Intellectual Property (IP) development.

With a global footprint of over 100 enterprise users in over 30 countries, Altizon is now a leading Industrial IoT platform provider recognized in the Gartner 2019 Magic Quadrant for Industrial IoT Platforms, for the second consecutive year.

2. Products

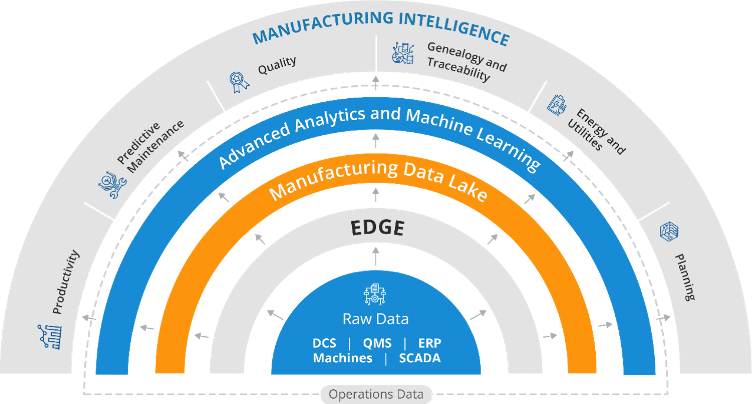

Datonis IIoT platform: Datonis Industrial IoT platform is a highly scalable, cloud-based IoT platform that acts as a manufacturing data lake and allows factory assets to securely connect and exchange information in real-time. Some of the prominent features are listed below:-

- Device management – The cloud-based platform facilitates management, control and upgrade of the connected devices in a secure environment.

- Real-time analytics – The platform permits streaming and analytics of data from the machines in real-time using a powerful real-time analytics engine that supports complex streaming logic.

- Machine Learning – The platform helps users interactively build and deploy powerful models to predict outcomes using a pre-built library of statistical and machine learning algorithms.

- Deployment Flexibility – Datonis is available as a cloud-hosted multi-tenant PaaS and it can be hosted on any cloud infrastructure or installed on-premise.

- Seamless Integration – Datonis can integrate IoT and operations data with enterprise IT systems such as Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) using pre-built adapters or an open Representational State Transfer – Application Program Interface (REST API).

- Alerts and Notifications – The platform generates real-time alerts and notifications on anomalies, thereby improving action-response effectiveness.

Datonis Manufacturing Intelligence (MInt): Manufacturing plants are a highly complex environment consisting of machines, automation systems and management software that generate a tremendous amount of data in silos. These data silos often result in decision making that might work for a specific area but miss out on the bigger picture. Datonis MInt is a manufacturing data lake for a digital enterprise. It can combine manufacturing process and Information Technology (IT) data from multiple operation sources like ERP, MES, Supervisory Control and Data Acquisition (SCADA), Distributed Control Systems (DCS) into a single data repository to deliver actionable insights. The data from this lake is then made available to different modules that help generate actionable insights in various verticals of the manufacturing value chain. Some of the prominent features are listed below:-

- Modules

- Productivity Analytics – MInt helps analyze productivity metrics such as Overall Equipment Effectiveness (OEE) and define actions to drive change.

- Machine Maintenance – MInt helps identify machine parameters that are critical to maintenance and build models that can predict performance degradation and breakdown.

- Quality – MInt enables real-time batch and product traceability through tracking across the manufacturing process to ensure compliance in the event of a product quality audit, withdrawal or recall.

- Energy and Utilities – MInt helps measure, analyze and optimize key consumables such as power, steam and compressed air, critical to a manufacturing process. Tracking of consumption pattern changes can help address inefficiencies in the process.

- Correlation Analytics – MInt helps analyze and corelate information across all the dimensions of a manufacturing process to identify Key Performance Indicators (KPIs) that matter most for an enterprise.

- Digital Twin – MInt creates a virtual replica of a physical product or process to identify and address problems before they even occur.

Source: Altizon

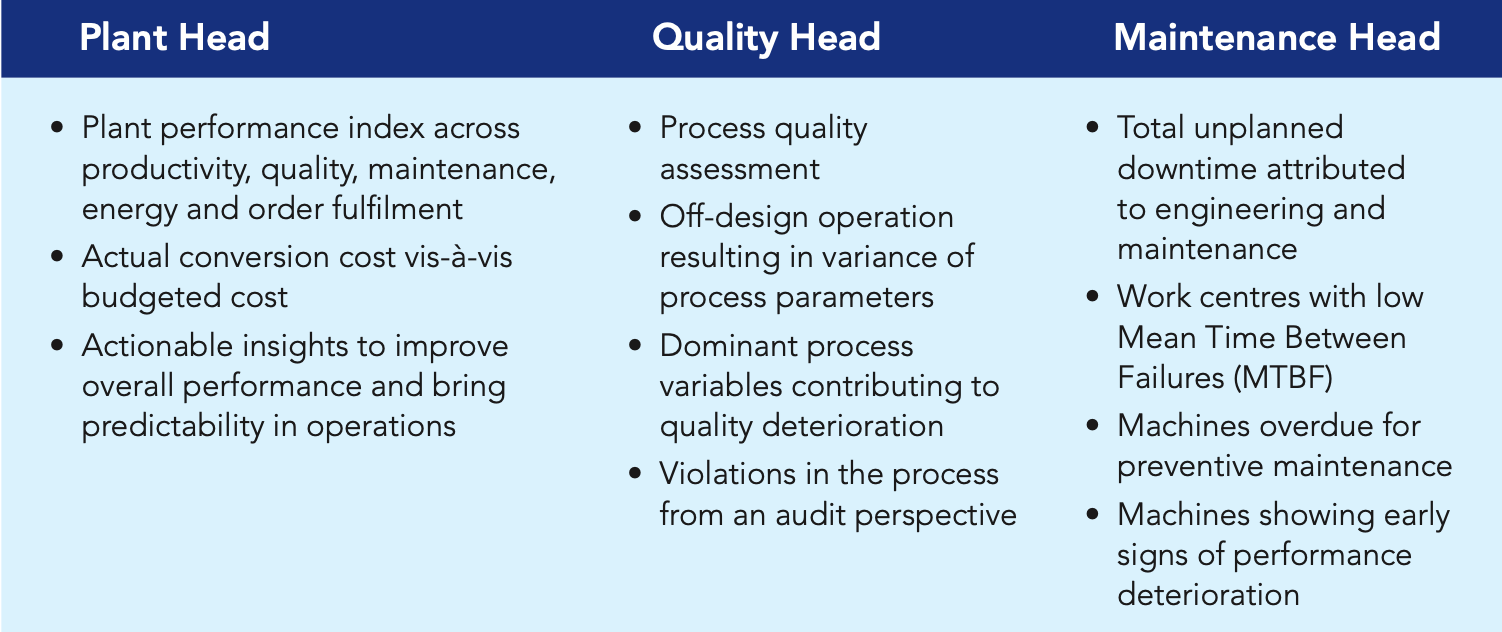

- Value-Chain Beneficiaries – The beneficiaries on the factory floor due to implementation of digitally enabled tools are summarised in the table below.

Source: Altizon

Datonis Edge: As IoT devices become more common and incorporate more processing power, vast amount of data is being generated on the outer “edge” of computing networks. This data needs to be sorted into structured identifiable formats, without introducing additional latency to the already time-sensitive process. Datonis Edge is a distributed computing platform that analyzes data from devices and systems closer to the source of the data. Edge is installed on-premise inside the factory network and can be installed on an industrial PC or on a virtual machine. It only requires a machine with an operating system, and the configuration of the machine depends on the amount of data to be processed. Edge deals with data at a very high latency and processes it by using simple mathematics or even advanced machine learning algorithms. The platform then ensures that part of this process data shows up in the industrial IoT platform for further analysis. Some of the prominent features are listed below:

- Industrial Connectivity – Edge helps rapidly connect machines and shop-floor IT systems to Datonis by using a pre-built library of Industrial and software adapters.

- Edge Analytics and Artificial Intelligence (AI) – Edge can help define analytics and AI-based machine learning models and pushed to the Edge for greater performance and faster response times.

- Scalability and Resilience – Edge can help set up a distributed, resilient and fault-tolerant infrastructure that never loses data. Increasingly, computing, storage, and analytics capabilities are compressed into IoT devices that can be situated nearer to end users. Edge computing therefore offers a less expensive route to scalability, allowing companies to expand their computing capacity through a combination of IoT devices and edge data centres.

- Custom Plugins: Data processing, device connectivity and system integration capabilities can be added using the Edge Plugin API.

- Device Management: Edge devices can be managed, secured, controlled and upgraded from the platform using a powerful policy engine.

- Security: Edge comes with the option for users to define key-based authentication for every connected Edge device and to set up specific policies.

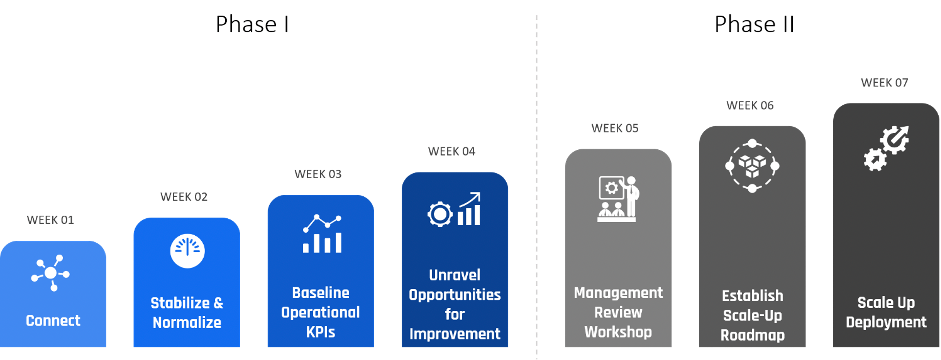

3. Implementation Model – 4 Week IIoT Challenge

Altizon has identified that many companies are wary of Industrial IoT implementation primarily due to apprehensions on the length of the transformation process timelines. To overcome customer apprehensions, Altizon has rolled out a 4 Week IIoT Challenge.

During the challenge, Altizon will work directly with participants to integrate a specific manufacturing process with Altizon’s Datonis platform, with the goal of leveraging machine data to improve Overall Equipment Effectiveness (OEE), improve process adherence and improve specific energy consumption, while delivering the foundation for a scalable enterprise-wide IIoT strategy.

As per Altizon, within 4 weeks of deploying Datonis participants would begin to uncover opportunities to improve base line productivity by 15% and process quality by at least 3%, along with a drop in energy consumption by 5%.

The implementation process entails:

Source: Altizon

Co-Founder and CEO Vinay Nathan believes that the implementation of IIoT into an organization does not have to be a lengthy or complicated process to deliver business results. “We are confident — and have proven — that manufacturers can unravel opportunities to improve business results from IIoT within four weeks,” he shares.

4. Success Stories

- A leading organization in technical textiles

- Problem Definition: The client wanted to accelerate their IoT-enabled digital transformation by connecting critical processes in the manufacturing of technical textiles. The focus areas included improving quality by analyzing parameters critical to the manufacturing process, optimizing fuel consumption, reducing power consumption, minimizing line breakages and improving overall productivity by predicting stoppages using condition monitoring. Some of the challenges that the solution needed to overcome included:

- A brownfield solution that would integrate with a fully functional line and existing IT systems

- Support heterogeneous machines with a variety of connectivity protocols

- Provide extreme accuracy and reliability as the system would be used as point of reference

- Support a set flexible, multivariate analysis techniques that suit a range of complex processes

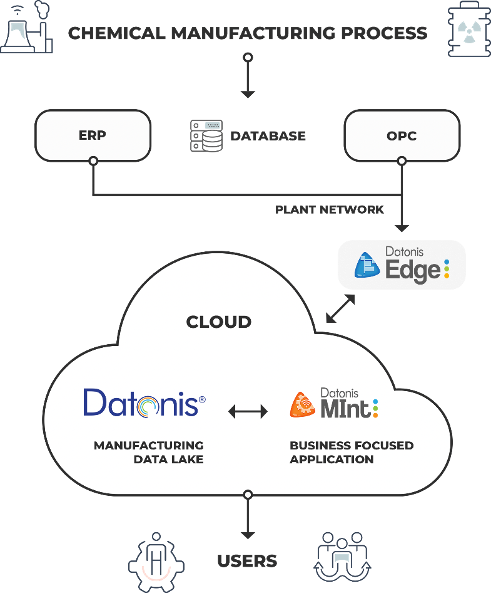

- Solution: Altizon’s Datonis IoT suite was deployed at client with Datonis Edge operating in a fail-safe configuration inside the customer’s network. Datonis IoT platform and MInt were deployed on the cloud. The Datonis IoT API was leveraged to integrate with all dependent systems including ERP.

Source: Altizon

- Benefits: The client leadership team identifies projects with payback ~1.5 years, to be able to assess the impact and plan ahead, as in the case of Altizon. The leaders determined key focus areas or use cases and began the implementation for one use case in one plant, moving on to other plants after a successful implementation. Post implementation the following key benefits were accrued: –

- 10% improvement in quality

- Reduced material wastage

- Real-time process visibility

- A leading global multinational in the CPG space

- Problem Definition: The company operated several warehouses, mostly closer to the last distribution point (large retailers). Products in various categories are packaged in specific delivery or display cartons at these facilities. As most CPG businesses consist of high volume with low margins, optimizing every operation and effective utilization of resources add up to profit margins. The key problem at these warehouses was the lack of visibility into reasons for machine breakdowns or idle time, thereby delay in delivery. The customer wanted to implement real-time line monitoring and alert system to gain control over downtime issues and implement improvement measures. Some of the implementation aims included: –

- A complex, wireless sensor-based tracking of line performance, along with plug and play sensors and hardware with minimal installation overhead

- A cloud-based, multi-tenant hosted platform as the single data repository for plant data across the globe

- Extreme accuracy and reliability as the system would be used as point of reference

- A highly customized application for business KPIs along with an open platform that provides the ability to easily integrate with IT systems

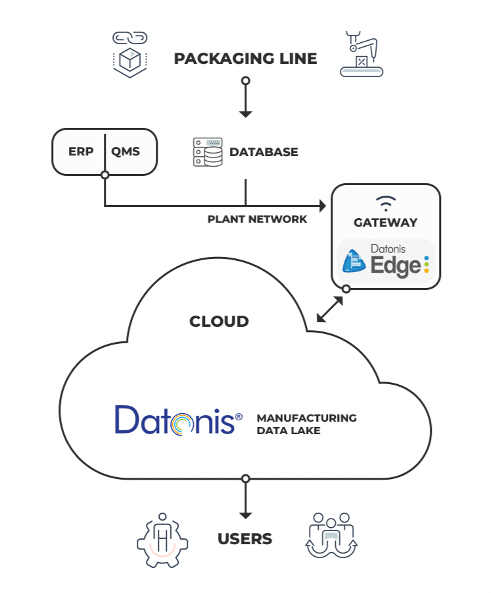

- Solution: Parts of the Datonis IoT suite were deployed. Wireless sensors and a hardware communication gateway with Datonis Edge embedded in it were deployed inside the customer’s network. Datonis IoT platform and a custom business application were deployed on the cloud. The Datonis IoT API was leveraged to integrate with all dependent systems including ERP.

- Benefits: Post implementation the following benefits were accrued: –

- 8% improvement in line performance

- Real-time visibility of process lines to identify downtime sources, inefficient teams and ageing equipment

- Real-time analysis of consumption of utilities such as power and water

Source: Altizon

- A leading tire manufacturer, among top 25 in the world

- Problem Definition: The client needed to drive IoT-enabled digital transformation by connecting critical processes in tire manufacturing. The processes included mixing, calendering, extrusion, cutting, winding and curing. Here’s what the implementation needed to achieve:

- A brownfield solution that would integrate with a fully-functional line and existing IT systems

- Support heterogeneous machines with a variety of connectivity protocols

- Provide extreme accuracy and reliability as the system would be used as point of reference

- Support a set flexible, multivariate analysis techniques that suit a range of complex processes

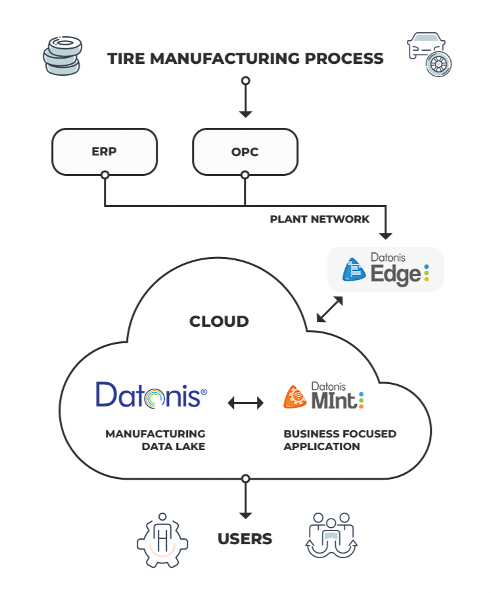

- Solution: Altizon’s Datonis IoT suite was deployed at the client site, with Datonis Edge operating in a fail-safe configuration inside the customer’s network. Datonis IoT platform and MInt were deployed on the cloud. The Datonis IoT API was leveraged to integrate with all dependent systems including ERP.

- Benefits: Post implementation the following benefits were accrued: –

- Reduction in mean time to repair

- Elimination of unplanned machine downtimes

- Improvement in productivity

- Reduction in cost of energy consumed per unit production

Source: Altizon

5. Key Findings

Early adopters of IIoT

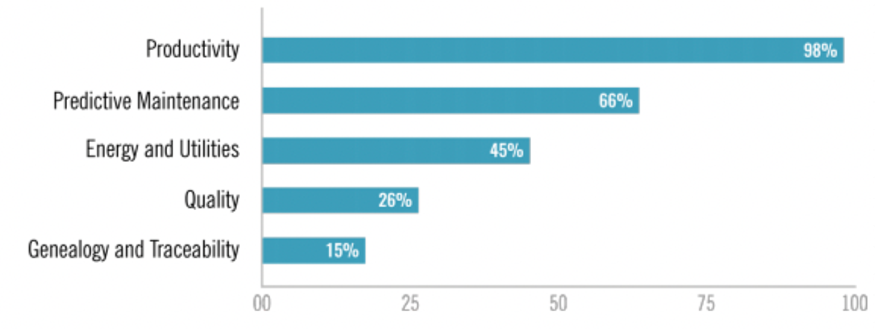

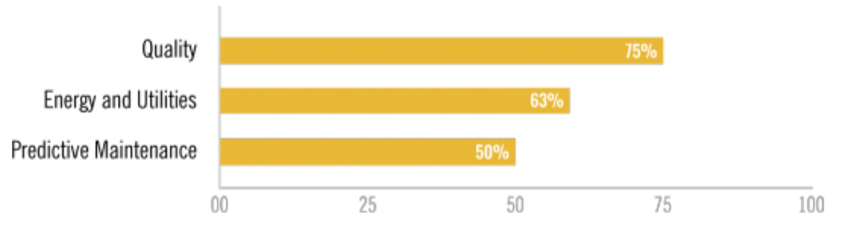

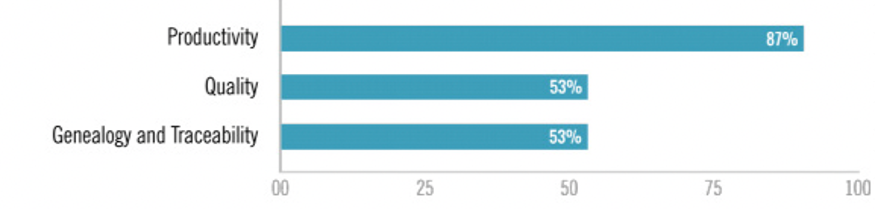

A study conducted by Altizon has mapped certain benefits accrued by early adopters of Industrial IoT. The details are depicted in Figure 6 to 9 below.

Source: Altizon

Source: Altizon

Source: Altizon

Source: Altizon

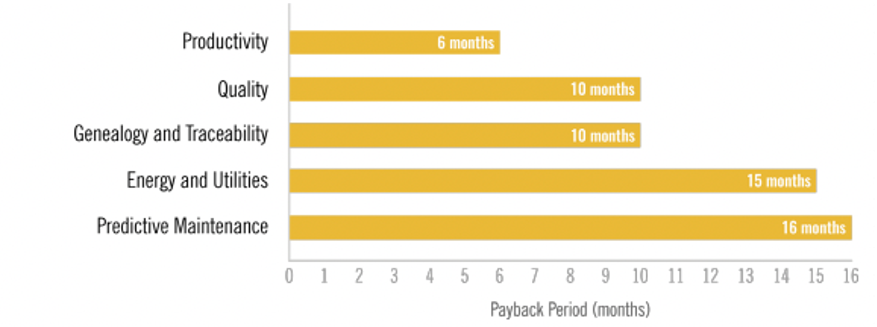

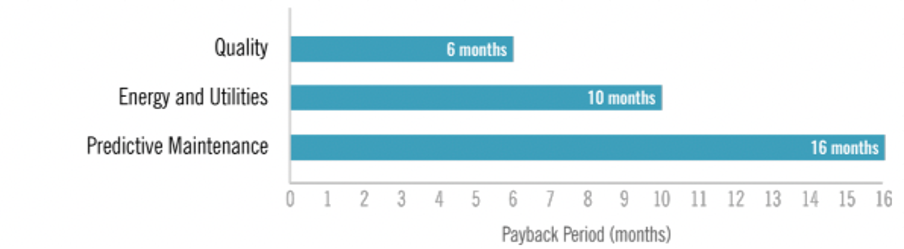

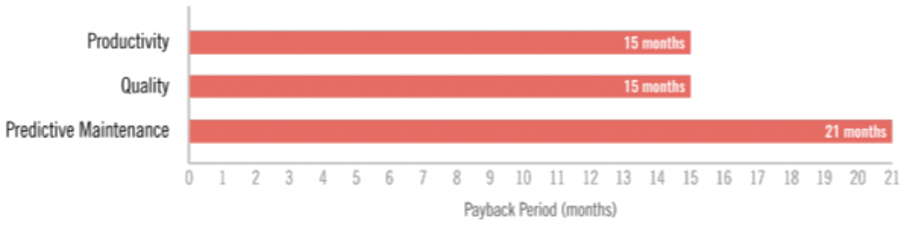

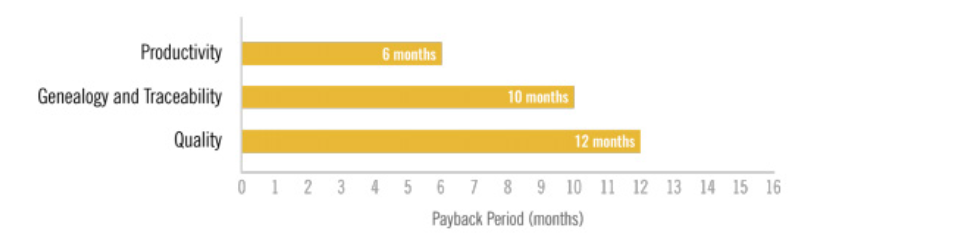

Payback Timelines

Altizon has also mapped the expected payback periods on investments in IIoT for early adopters.

The details are depicted in Figure 10 to 13 below.

Source: Altizon

Source: Altizon

Source: Altizon

Source: Altizon

- Altizon’s inclusion in the Gartner IIoT Magic Quadrant has helped it gain global recognition for their products and services. A similar recognition within the Indian Industry 4.0 start-up ecosystem will be useful to identify leaders in various verticals.

- Adoption of IIoT will result in freeing up engineers from management related jobs and aid them in getting back to their core profession.

- Adoption of IIoT in India is yet to gather momentum when compared to U.S. and European markets.

Commander Amrut Godbole is Fellow, Indian Navy Studies Programme, Gateway House.

Manjeet Kripalani is Executive Director and co-founder, Gateway House.

Sagnik Chakraborty is Former Researcher, Cybersecurity Studies Programme, Gateway House.

This study was conducted by Gateway House, in partnership with India EXIM Bank. Read the full study here.

For interview requests with the authors, or for permission to republish, please contact outreach@gatewayhouse.in.

Disclaimer: The contents of the paper are personal views of the author and do not reflect the official position of the Indian Navy or Government of India.

© Copyright 2021 Gateway House: Indian Council on Global Relations. All rights reserved. Any unauthorized copying or reproduction is strictly prohibited.